Innovative Water Treatment Systems in Agriculture & HVAC Systems

Dan Cook, President

Conservation Solutions Corporation

Dan Cook discusses several water treatment technologies for agricultural applications to reduce the surface tension of water, resulting in better hydration and uptake of minerals in plants. As a result, there is a significant reduction of water in irrigation systems as well as increased crop yields. These water treatment systems can also increase the throw of water in pivot irrigation systems, improve drip irrigation, and reduce pump energy costs and the use of chemical fertilizers. Precision agriculture may be used to avoid overwatering.

Cook also discusses Pulse Power Electronic water treatment, Sphagnum Moss, low dose ozone, UV systems and high efficiency filtration systems in HVAC applications, swimming pools and spas. These systems have a proven track record of eliminating the use and discharge of hazardous chemicals into the environment. The technologies enable energy, water, and sewer cost-savings, eliminate hard rock calcite scale and biofilm, control bacteria/legionella, and make the commercial, institutional, industrial, or healthcare buildings more sustainable. Uncontaminated blow-down water from cooling systems can be used for secondary uses, such as irrigation, green roofs, decorative fountains, fire retention ponds.

The webinar, with Q&A, is broken into 7 videos.

Part 1 - Innovative Water Treatment - Introduction

Cook provides an overview of the water treatment technologies for agricultural applications and HVAC applications.

The combination of water scarcity and the exponential increase of groundwater use will result in used up fossil/confined aquifers (Groundwater Flow Diagram). To better understand the water challenges, Cook discusses a study on the average groundwater recharge and storage of all African countries (Link, Figure 4). In addition, he covers the correlation between water hardness and water quality, water use, as well as the impacts on the piping equipment. A water hardness map of the US illustrates how different US regions may face different challenges (Hard Water Map).

The benefits of water treatment systems are seen in the reduction of water use, protection of equipment, and the reduction of hazardous chemicals in agricultural and process applications. Six principles drive the operation of magnetic and electronic pulse power water treatment systems. These are (1) Faraday Effect, (2) Moses Effect, (3) Crystallization, (4) Sodium Salts, (5) Magnetic Flux Density, and (6) Centrifuge Effect.

Cook discusses another water treatment technique, the Sphagnum Peat Moss, which is based on metal absorption changing the way Calcium forms in solutions.

Part 2 - Innovative Water Treatment in Agriculture

Cook presents several agricultural technological products that reduce water use and improve crop production.

The use of Neoddenium Magnets (Link) to enhance seed germination achieved significant improvement in crop production. The magnet-treated seeds tend to increase starch protein production and improve the root structure and turf density. In the US Midwest, the Magnation’s seed maximizer increased corn production.

The Rainbolt irrigation systems (Link) reduce surface tension of water, yielding faster crop growth and reducing pump costs. The Rainbolt systems are applied to drip or pivot irrigation in hydroponics. They can also be inserted in a hose for use in backyard gardens and greenhouses.

The Turbulator (Link) creates turbulence, which reduces the surface tension of water. The use of turbulators for irrigation of large areas leads to healthier soil, better plant hydration, and faster plant growth.

Part 3 - Pulse Power Electronic Water Treatment Technologies

Cook discusses several revolutionary energy-saving conductive pulse power technologies.

The Flow-Tech Electronic systems (Link) are chemical-free systems that improve safety, help the environment, and save money. The Flow-Tech conductive pulse power systems’ effectiveness is manifested in higher energy intensity and significant reduction in bacteria levels and legionella amplification, and also in avoidance of hard rock scale and corrosion.

These conductive pulse power systems work in tandem with a control panel that is connected to the water pipe and controls the operating frequency. An electric field is created with charged particles throughout the pipe.

For HVAC application, water hardness can have significant impact, so it needs to be addressed. If the water is soft or low calcium, then a corrosion inhibitor is needed to avoid corrosion issues.

Water cooling systems, which are a lot more energy efficient than air cooling, consist of a conductivity meter, corrosion inhibitor, coupon rack and blowdown to maintain conductivity setpoints. The whole system is charged electronically so that a significant amount of water is saved on the blowdown by doubling the cycles of concentration in the conductivity, with no use of chemicals.

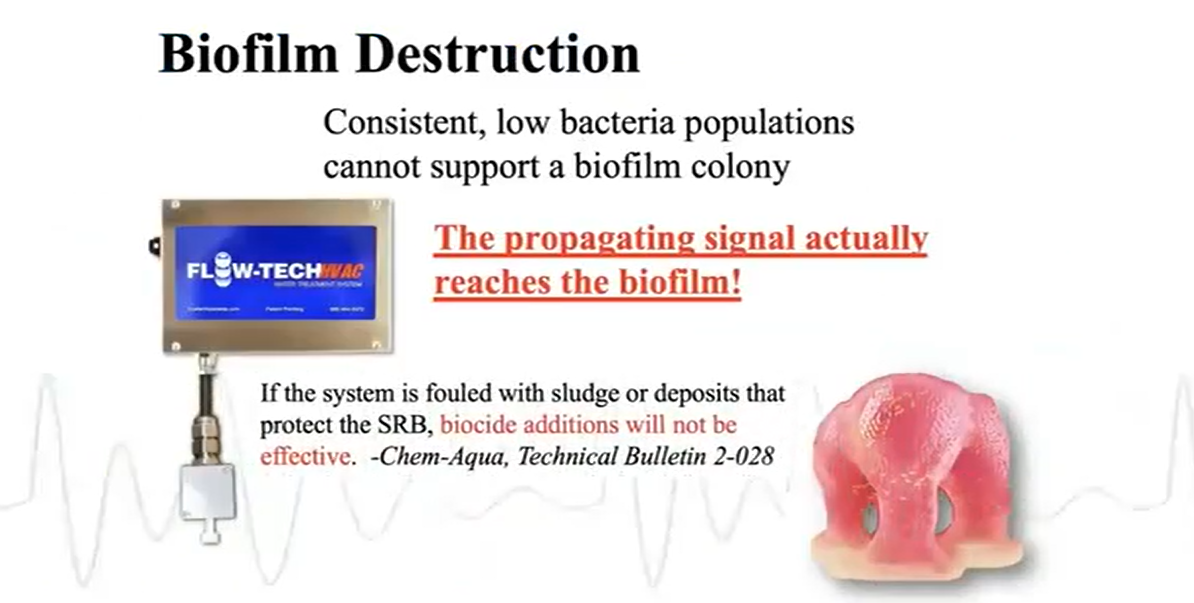

Encapsulation in these cooling systems prevents bacteria from reproducing in a 24- to 48-hour period, resulting in their elimination. It is achieved by the electro-perforation of the cell walls of the bacteria.

Part 4 - Water Treatment in HVAC Systems

Cook discusses the use of Flow-Tech systems to eliminate scale in HVAC applications without the use of chemicals, resulting in significant energy savings. Reduction of Bacteria levels using pulse frequency systems are highlighted as well as avoidance of legionella amplification by destroying the amoeba biofilm.

Part 5 - Applications of Pulse Power Systems

Flow-tech technology is used in several applications, such as cooling towers, hospitals, power plants, wastewater treatment plants, municipal water districts, wells, and commercial buildings. As an example, an apple grower experienced calcite scale buildup on a pivot watering system. Using a flow-tech system to treat the water used for irrigation, the farmer was able to control scale without chemicals. The suspended calcium formed on the apple can be easily dusted off. Other positive outcomes were observed when these electronic systems were installed on potato farms, in power plants, and marijuana facilities. These Flow-Tech systems also managed to reduce Legionella to negligeable counts and inhibit biofilm growth in a hospital.

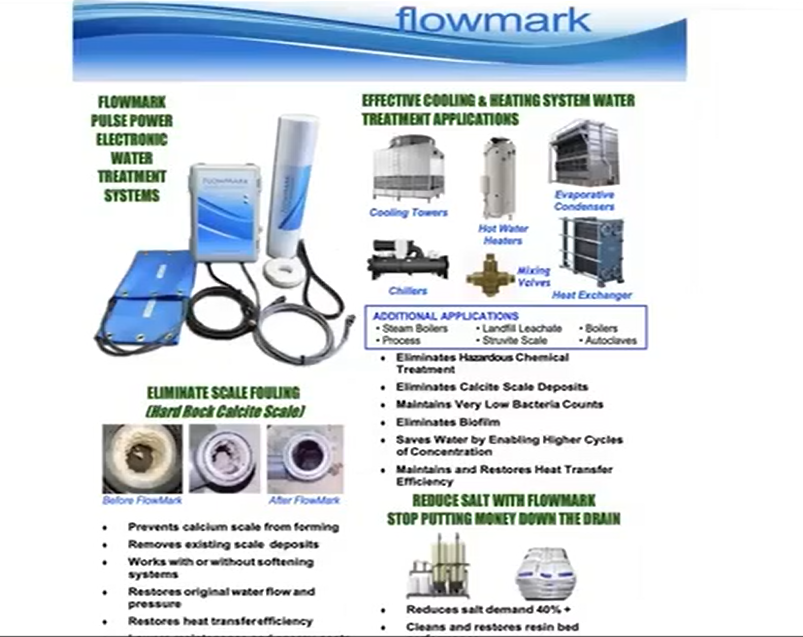

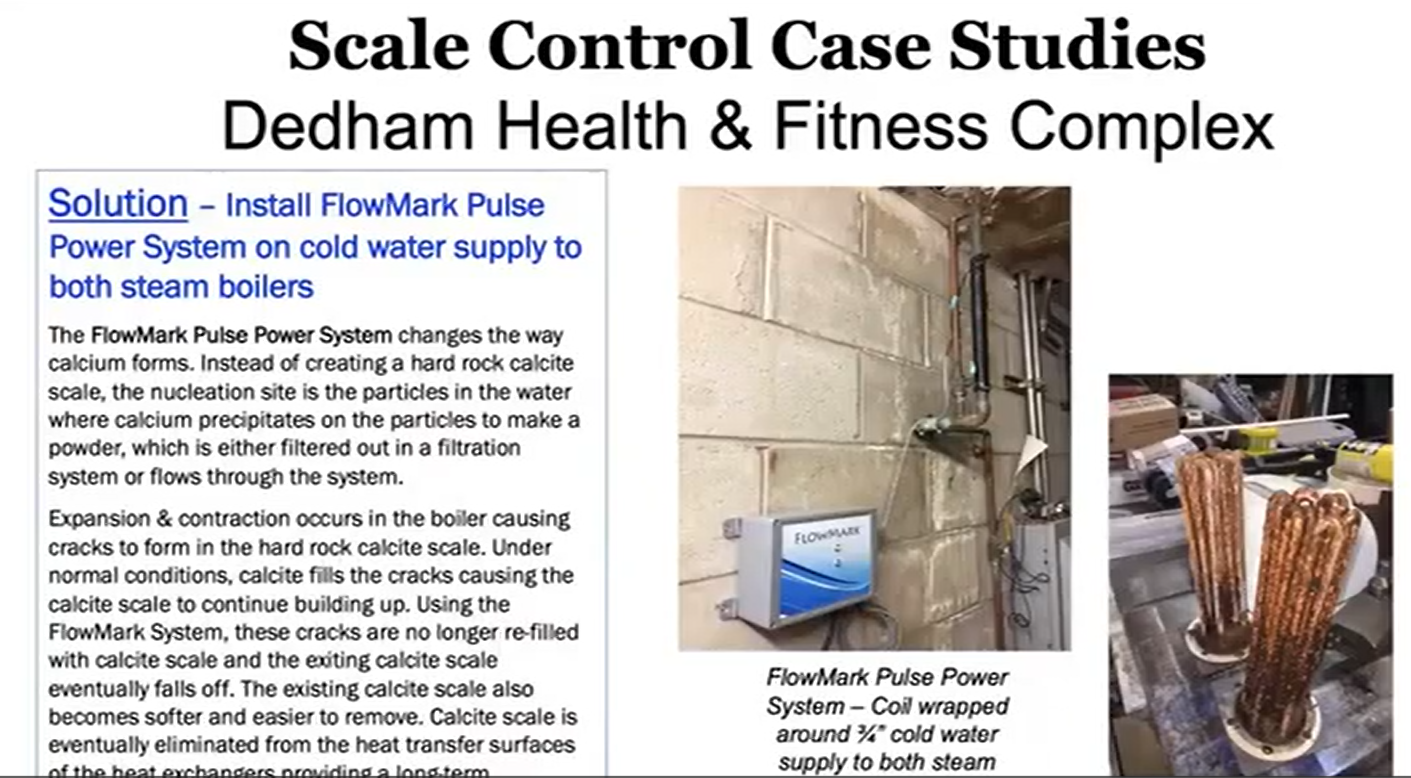

FlowMark is another technology, like the FlowTech, but a smaller system. FlowMark can operate as an efficient water softener. These units are used in landfills to avoid groundwater contamination. FlowMark units also eliminate scale build up in rain drainage pipes.

FlowMark low-dose Ozone Systems is another technology to control bacteria. It can be combined with a Sphagnum Moss system to handle high bacteria counts in poor-quality water applications.

Algae is controlled on Pulse Power systems and its growth reduced by blocking sunlight.

Cook also discussed how uniform corrosion can be controlled in Pulse Power systems. For these systems, the calcium carbonate is a natural Cathodic inhibitor.

The primary types of corrosion that may affect these pulse power systems are localized corrosion due to chlorine-pitting and microbial corrosion due to biofilm.

Part 6 - Corrosion and Scale Control Case Studies

Cook discusses the handling of scale issues in steam boilers using chemical-free innovative technologies.

Participants brought up the challenges of polluted water in Uganda due to flooding and wastewater contamination. Lake Victoria, a major source of drinking water, needs an approach to control the effluent going into it, filtering water supply, and protection from raw sewage leaks.

Many commented on stopgap measures to provide potable water in public fountains and alleviate the lack of drinkable water to underserved communities. Municipalities would be able to manage water fountains and implement safe and reliable measures for drinking water. The water treatment technologies that Cook presented can be adapted to eliminate scale in pipes, reduce bacteria levels, and reduce the levels of contamination. In addition, potential sustainable solutions, near the rivers or lakes, can be implemented to avoid flooding damage and contaminated wastewater from treatment plants.

Part 7 - Chemical-Free Sphagnum Moss Water Treatment

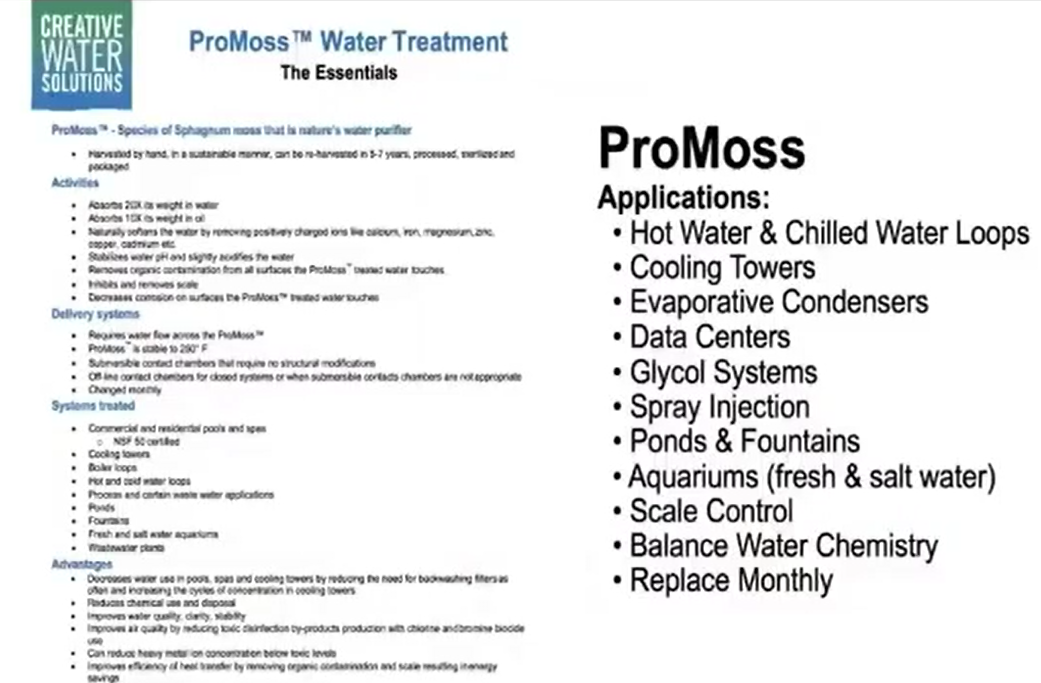

Cook presented several case studies with ProMoss (Link), a Sphagnum peat moss technology, with applications in museums, wastewater plants, and industrial buildings where the HVAC water is kept clean and with significantly low bacterial levels. ProMoss is a chemical-free water treatment in cooling towers, boiler loops, hot water chill, and process applications. Sphagnum peat moss eliminates disinfection by-products and volatile organic compounds. Sphagnum moss absorbs calcium and prevents scale formation. It can also be inserted in the inflow to clean up small ponds, water fountains, and fresh or saltwater aquariums.

PoolNaturally Plus System (Link) is used in indoor pools and spas to avoid the use of chlorine. Instead moss in lobster traps is used for water filtration.

Cook talked about another related technology, PhaseStore (Link), which uses bio-based phase change material (Bio-PCM) for thermal energy storage. Bio-PCM adds cooling capacity and avoids high energy demands by shifting modes to night-time when energy demands are low. BioPCM can also act as an energy blanket in transportation of frozen food in refrigerated reefer trucks.

The UVC system is an ultraviolet disinfection method that uses short-wavelength UV light to reduce micro-organisms. These UV light sanitizing systems are installed in school air conditioning systems to kill germs.

Magnation technology (Link) treats drinking water magnetically to reduce the surface tension on water. This process results in improved taste and other health benefits such as better hydration.